Overview of Drying Technologies

Effective drying is often the crucial step in many production operations. In addition to its obvious importance in generating an attractive and usable product, it is frequently utilized to facilitate product handling, reduce shipping costs, increase other process equipment capacities, and optimize product integrity during shipment and shelf life during storage.

Merely placing a wet solid material in an oven and applying heat will eventually produce a dry product. A low or high speed tumbling device will, after sufficient time, have the same result. Tray drying is yet another time-consuming method of drying a product. All of these materials focus on one objective – drying – without respect to temperature sensitivity of the product, volatility of the materials, flammability of the volatiles, friability or shear sensitivity of the product, cycle time considerations, environmental constraints, and pre-or post-drying processing steps.

Fluidized Bed Mixing Action

(shown at 1/200 second exposure)

In simple terms, there are just two conditions for drying materials – atmospheric and vacuum. In either condition, the objective is to remove volatiles from a west solid material.

Littleford Ploughshare® Dryer

The key to Littleford state-of-the-art drying technology is the unique, mechanically fluidized ploughshare action which agitates and individualizes the solid particles to be dried. This ploughshare action within the horizontal, cylindrical Littleford vessel forces the product into a three-dimensional motion that individualizes each particle, continuously exposing tremendous particle surface area for drying. The particles constantly contact one another and the heated interior walls of the jacketed Littleford vessel, furthering the drying process.

Additionally, Littleford Ploughshare Dryers, equipped with independently operated, high shear “chopper” devices, reduce the particle size of the lumps or agglomerates to expose undried materials and ensure thoroughly dried particle interiors. Deagglomeration further shortens the drying time required.

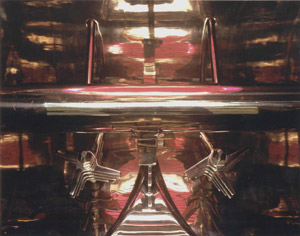

Inside Littleford Ploughshare Dryer

(mixing plow and choppers)

Drying Comparison

A comparison of operational parameters of atmospheric and vacuum drying is helpful in selecting the most effective drying for your product.

|

ATMOSPHERIC DRYING IN A

LITTLEFORD PLOUGHSHARE DRYER

(with dry gas purge)

Batch temperature during drying cycle is near the atmospheric boiling point of the volatiles being removed. Atmospheric drying is excellent for many materials but usually not suitable for temperature-sensitive materials.

Large volume of gas/air in the vapor stream makes solvent recovery expensive. Atmospheric drying is not recommended for flammable solvents or where environmental restrictions are imposed.

Non-saturated atmosphere works very well with shear-sensitive materials.

Drying cycles are substantially shorter than the other types of dryers but are not as efficient as vacuum drying because of smaller temperature differential (jacket to product) available for drying. |

VACUUM DRYING IN A

LITTLEFORD PLOUGHSHARE DRYER

Batch temperature during drying cycle is much lower than the atmospheric boiling point of the volatiles being removed. Vacuum drying is excellent for temperature-sensitive materials.

Entirely enclosed system makes solvent recovery very easy, and works well with flammable solvents or where environmental restrictions are imposed.

Saturated atmosphere necessitates parameter changes to the process including speeds to avoid over working shear-sensitive material.

Drying cycles are shorter because of larger temperature differential (jacket to product) due to the lower boiling point under vacuum conditions. |

| Both the Littleford atmospheric and vacuum drying processes are based on state-of-the art mechanically fluidized bed mix action augmented by the high shear chopper, the combined effect of which leads to Littleford efficient thermal processing technology. Although the atmospheric dryer is efficient in drying shear-sensitive materials which are not temperature limited, a vast number of drying applications require lower temperature processing and/or shorter cycle times. Thus, in most applications, the highly efficient Littleford Ploughshare Vacuum Dryer is the recommended drying process. |

|

|